Republic of Kazakhstan, 130000, Mangystau Region,

Aktau, Industrial zone No. 6, site No. 91/2.

+7 7292 544 750

info@osskz.kz

About us

Founders

Health and Safety

Machine equipment

Quality

Manufacturing

Customers

Vacancy

Charity

Completed orders

Contacts

MANUFACTURING

List of the manufactured equipment

Pumping unit

The pumping unit Hudson is the modernized PNSh-80,SKDR-8,PShGN-8 repeating all technical characteristics of a prototype. Hudson differs from the predecessors in a number of advantages. Besides, the main knots Hudson are completely interchanged with pumping units of earlier production. The pumping unit is equipped modern telemetric the equipment and an intellectual control system. This model is developed with respect for all technical standards of safety of production and answers high requirements of quality.

standard size

HUDSON

80-3-40

HUDSON 80-3-40-01

HUDSON 80-3-40-02

HUDSON 80-3-40-03

Pump

The boring pump BP-125 — horizontal, two-cylinder, bilateral action, driving with the built-in gear reducer. The pump is intended for forcing of washing fluid when drilling oil and gas wells, for forcing of liquid environments when performing flushing and squeezing works in the course of workover, for water injection in layer for an oil production intensification, for pumping of various nonaggressive liquids, including the flooded oil.

Designation of the pump

Execution

Dimensions, mm

Weight, kg

BP-125-01

Without pulley and a frame

2353X886X1960

2740

BP-125-02

With a pulley and without frame

2353X980X1960

3100

BP-125-03

With a pulley and on a frame

2353X980X2005

3190

at the request of the customer all models can be modernized as it is constructive and intellectual

Pumping unit

High-pressure pumps of the CSP type are designed for pumping clean water, aggressive and non-aggressive oilfield water into oil tanks. It is used in the oil industry, metallurgical enterprises, mining enterprises.

CSP HUDSON — centrifugal sectional pump; 180 – flow, m3/h; 1422 – head, m; O – execution of General industrial; K – performance corrosion-resistant; C – shaft seal; T – shaft seal face

CSP 45-1900

CSP 240-1422

CSP 180-1900

CSP 180-1422

CSP 90-1400

CSP 630-1700

CSP 220-1422

CSP 180-1050

X-mas tree

Fittings fountain (Christmas tree) is part of the wellhead equipment and is designed for the equipment of the mouth of the surface of the fountain oil and gas wells in order to seal the mouth, its binding, suspension of the tubing lifting column, installation of ESS, control and regulation of the mode of operation of wells, overlap and direction of the extracted products in the pipeline, as well as for the necessary technological operations on the well. The fittings of the fountain AFK are installed on the column strapping of wells in the process of their development and testing. Through the fountain fittings (Christmas tree) carry out technological operations and the descent of downhole equipment, tools and devices

Working environment

Production of oil and gas wells

Climatic version

HC

Operating ambient temperature range

FROM -60 TO +40

Working medium temperature

+120 C

The way of suspension of downhole tubing

In the sub to the pipe head

Equipment to a wellhead

The presented equipment for strapping casing is part of the wellhead equipment and is designed for strapping casing. It is also possible to carry out such technological operations as pressure reduction in the inter-column space, injection of cement and other plugging materials into the inter-column space, etc. The column head, by means of which casing strings are tied and suspended during drilling and operation, also serves as the basis for installation of fountain fittings and pressure control in inter-column spaces. Packers are provided for reliable sealing of inter-column spaces. As a shut-off device manifold units strapping of columns used valve type VMT. Today, our enterprise has developed a full range of equipment to wellhead. Any modifications and sizes of strapping are possible for different conditions of use in fisheries.

Column equipment

Column equipment for wellhead strapping with Muff suspension is designed for strapping the upper ends of two adjacent casing strings protruding above the wellhead, in order to suspend the columns, sealing and disconnecting the space between them and controlling the pressure in it during drilling and operation of wells.

Flange transition

The transitional flange is designed to connect the fittings of the fountain or blowout equipment to the column head.

at the request of the customer all models can be modernized as it is constructive and intellectual

Cable entry

The cable gland is designed to seal the cable cores passing through the fountain valves equipped with ESS. Cable gland provides high tightness during well operation. The use of cable entry VK1/VK2 provides ease of installation and dismantling operations. The versatility of the cable entry is determined by the diversity of the diameters of the holes for the cable cores and connecting threads.

Manifold pipes

Manifold pipes – a part of the pipeline of a certain length for quick connection between themselves and other units or equipment, the connection can be carried out with the help of BRS or flanges. Manifold pipes are used in the oil and gas industry in process pipelines to combine components and equipment together for the purpose of transporting working media. The working medium can be a variety of substances: water, oil, petroleum products, alkalis, inhibited acid solutions, cement and clay solutions, and other process fluids.

Manifold pipes

Connections hinged (SSh, the EDS) are connecting elements of pipelines which are used for connection and orientation of quickly combined pipelines.

Pipelines connect pump installations with well head fittings at hydrosanding perforation, a hydraulic rupture of layers, cementation of wells in the course of drilling and workover, washing of sandy traffic jams, acid processings of wells and other technological operations.

Connections hinged allow to change quickly flow direction of a working environment and to bring together network of pipelines of various configurations.

Valves

Precast valve with a gate operating inside the housing and installed at an angle of 90° to the pipeline, is used to seal the flow of the working medium. The valve is a reliable locking mechanism operating under high pressure. The main materials - gate and saddle, made of alloy stainless steel with volumetric hardening and coating, resistant to wear and bullying. This type of valves is recognized as the most reliable and easy to operate

L, мм

Title

Du, mm

MPa, (psi)

Mm

Н, мм

295

245

350

560

560

620

50x14 M

50x14 M-P

65X14 M

D 195

65

50

14(2000)

D 165

tubing 60

D 215

tubing 60

D 195

D 245

D 195

D 245

370

245

350

422

350

422

560

560

500

500

500

500

50X21 M

50X21 M-P

1 65X21 M

2 65X21 M

1 65X35 M

2 65X21 M

50

50

21(3000)

35(5000)

Ball valve

Precast valve with a gate operating inside the housing and installed at an angle of 90° to the pipeline, is used to seal the flow of the working medium. The valve is a reliable locking mechanism operating under high pressure. The main materials - gate and saddle, made of alloy stainless steel with volumetric hardening and coating, resistant to wear and bullying. This type of valves is recognized as the most reliable and easy to operate

Reservoir

Underground storage tank and underground with heater are used to store fuel or other fluids. Tanks have two high necks, one of which is used to install the pump, and the second is used as a manhole. Tanks with and without heating are made with conical bottoms, but in some cases elliptical bottoms are used. Internal cooling coil capacity of the serves to maintain a predetermined temperature environment in the tank. At the request of the customer, it is possible to apply protective coatings inside the tank, as well as complete the tanks with all necessary valves and pumps.

8-20000-1300

8

2.8

12,5-2000-1300

12,5

3,25

16-2000-1300

C16

3,61

25-2400-900

25

4,36

40-2400-1000

40

5,95

63-3000-1000

63

9

Gas separator

Grid gas separators of the GS type are the equipment intended for final purification of gas from liquid environments, in particular from oil. Gas separators have a wide range of applications. They can be used in chemical, oil and gas production plants, underground storage, etc. Technical parameters The gas separator of type GS 1 and GS 2 is a vertical cylindrical container, while GS1 has no inspection hatch, but is equipped with a housing flange connector. Both types of mesh separators can be thermally processed, and also have details for fastening of thermal insulation. The type of device, its volume, composition of instrumentation and other technical characteristics are determined by the specific tasks and requirements of the client.

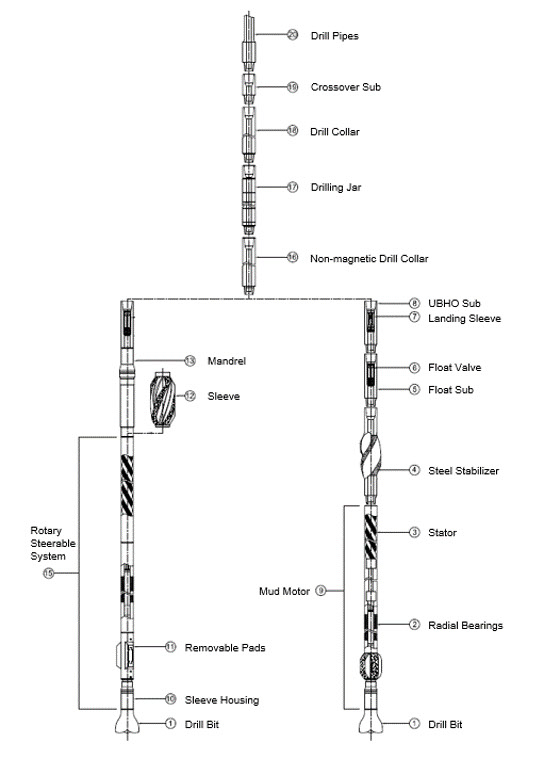

Alloy Steel Stabiliser

Our alloy stabilisers are manufactured from AISI 4145 H Modified Steel specifications, fully heat treated to the required Brinell Hardness Testing and yield strength requirements. The spiral stabiliser blades are machined to provide maximum mud circulation and are hardfaced to provide tough wear resistance. The thread connections are machined and gauged to required specifications

Non-Magnetic Drill Collar

Our Group’s non-magnetic drill collars are manufactured from heat-treated material for optimum strength and ductility in the critical threaded surface. These drill collars are made from selected bars of chromium molybdenum alloy steel with chemistries specially formulated for down-hole tools.

Stabiliser Sleeves

Our stabiliser sleeves are available in different configurations and are manufactured from a single piece of material (AISI 4145 H Modified Steel, AISI 4140 Steel or non-magnetic grades) for optimum integral strength.

Pup Joints

Our pup joints are manufactured from chromium, molybdenum alloy steel which conforms to AISI 4145 H Modified Steel specifications or other types of materials specified by customers. These pup joints are fully heat treated to the required Brinell Hardness Testing and yield strength requirements, and supplied in accordance to required specifications.

at the request of the customer all models can be modernized as it is constructive and intellectual

Crossover Subs

Our crossover subs are manufactured from AISI 4145 H Modified Steel, in accordance to requirements of required specifications and can be manufactured in various sizes and lengths to meet customers’ needs. Thread roots can be cold rolled and phosphate to minimize galling.

MWD / LWD Components

Our Group provides turnkey manufacturing of components that are used to assemble into MWD and LWD tools. Many of these products require the use of exotic materials such as superalloys (also known as high-performance metal alloys

Repair and Maintenance

Under our Repair and Maintenance business segment, our Group repairs and rethreads tools and components for customers so that these tools and components can be re-used. Such tools and components include alloy steel stabilisers, float subs, drill collars, drilling jars, crossover subs and drill pipes.

Machining Services

Our Group has the expertise to repair customers’ tools and components to help reduce their inventory costs by extending the useful lives of these tools and components. Pitted surfaces on the external and internal diameter of the tools can be removed by turning down or boring through these surfaces. Threaded connections can be rechased, refaced, or recut.

Hard-facing

Our Group offers a complete range of hard-facing of tools to suit various drilling conditions. We have leveraged on our experience and technical know-how to improve on, and to develop expertise on, wear resistance and other characteristics as well as matrix hardness. Stabilisers are typically shipped back to our Group to strip the worn hard-facing of a tool, reapply the required process by coating the tool with carbide, grind it back to the specified size, and then delivered back to customers for continued drilling operations. This will allow our customers to prolong the useful lives of the tools.

OSS KAZAKHSTAN

ALL RIGHTS RESERVED